PROFESSIONAL AND SEMI-PROFESSIONAL

HIGH PRESSURE WASHERS

Comet professional and semi-professional high pressure washers.

The pump is the core of the high pressure washer and relying on a Comet washer, since we are the leading company in the design and construction of pumps for agriculture and industry, means choosing a product of guaranteed quality, completely manufactured in Italy with highly valuable know-how.

The pump pressurizes water to create a powerful jet able to disintegrate and remove dirt. The higher the pump’s performance and reliability, the higher the washer’s performance and reliability.

The Comet range of high pressure washers has been designed to fully satisfy all cleaning and sanitizing requirements, both at home and in the professional field.

Each application has specific requirements in terms of power, pressure, temperature and accessories, our line ranges from domestic to professional heavy-duty use, ensuring excellent performance and a guarantee of long life and reliability for any use.

What is a high pressure washer (pressure, flow rate, temperature and power)?

The high pressure washer is a machine that, thanks to a high pressure water jet, removes dirt and incrustations from any solid surface.

Water coming from a water source (around 2 bar pressure) is pressurized (up to 500 bar) by means of a piston pump powered by an electric motor or endothermic engine and flows out through a nozzle mounted on a lance, thus succeeding in disintegrating and removing the dirt present on the surface to be treated.

The four fundamental variables that characterize and distinguish high pressure washers are:

- Pressure

Represents the force with which water escapes from the nozzle of the lance, i.e. the force that the water exerts on the surface to be washed. It is commonly measured in bars.

One must distinguish between: maximum pressure (P max) which is the maximum pressure at which the high pressure washer can be subjected and working pressure (P) which is the actual working pressure. - Flow rate

Represents the amount of water that the high pressure washer is able to pump in a given unit of time. It is commonly measured in l/h.

Here, too, a distinction must be made between maximum flow rate (Q max): the amount of water delivered by the high pressure washer with nozzle-free hose (i.e. without nozzle) and working flow rate (Q): the amount of water delivered to the nozzle of the high pressure washer with the pump at working pressure (P).

- Temperature

Depending on whether water is heated by a boiler after being pressurized by the pump, a distinction is made between cold water high pressure washers and hot water and/or steam high pressure washers.

- Power and type of motor

The power of the motor defines the “size” of the high pressure washer and identifies its fields of application, expressed in HP (Horse Power) or kW.

For standard domestic use it is sufficient to remain within 3.0 kW. For more complex or professional uses, it is instead necessary to choose models with higher powers (but a three-phase power supply is also necessary) or opt for a high pressure washer with an endothermic engine (combustion engine).

These variables are related to each other so, when selecting a high pressure washer, you have to carefully take in consideration the flow rate / pressure ratio, in order to find the most suitable solution for your needs and applications.

In the same way the power of the motor is related to the pump to be driven: the higher the pump’s flow rate and pressure values, the more power its motor will need.

Cold and hot water high pressure washers

As mentioned before, high pressure washers can be distinguished mainly in two categories in relation to the temperature of the water used:

- Cold water high pressure washers

They only use the water pressure supplied by the piston pump.

They can be used with chemical cleaners and can perform most cleaning operations including the removal of dirt and incrustations.

The situations in which we can successfully use a cold water high pressure washer are many and range from hobby and domestic uses to more industrial and professional uses.

- Hot water/steam high pressure washers

They are equipped with a boiler which, through a coil, heats the water coming out of the piston pump. They are used to remove grease and oil originating from hydrocarbons or compounds of vegetable and animal origin, as the high temperature facilitates the dissolution of oily dirt.

Hot water high pressure washers are used in various sectors, such as the technical agriculture, food industry and general industry and are an excellent solution for the cleaning of machinery, machine tools, engines and transport equipment. They are also an excellent means for sanitizing things and environments.

All high pressure washers, whether cold or hot water, are able to achieve the same type of result, i.e. the cleaning of a surface.

But then, which one to choose: a hot water washer or a cold water washer?

Basically what distinguishes them is how the result is achieved:

- Heat increases the molecular velocity of the cleaning agents that penetrate dirt particles more easily

- Molecular agitation performs the same function as heat, but exploiting the pressure of the water hitting the surfaces

- The detergent breaks the chemical bonds that have been created between dirt and surfaces and, through reagents, emulsifies oil and grease, allowing them to bond with water

It is therefore clear that, the results being equal, a hot water machine will need less detergent and/or pressure as the heat will be important in activating the molecular bond between the particles.

In addition, if we use cold water to remove a spot of grease the result will be mainly to create many hydrogenated micro-particles that, like a wax, will scatter over the entire surface. Cold water washers, however, have other advantages linked to lower costs and reduced energy consumption.

Let us therefore try to summarise the advantages and drawbacks of cold water and hot water washers:

| COLD WATER WASHERS | HOT WATER WASHERS |

|---|---|

| ADVANTAGES |

ADVANTAGES |

| Lower cost | Faster cleaning time |

| Less maintenance required | Less chemical detergents used |

| Smaller size due to the absence of the heating system | Increased effectiveness on oils and greas |

| DRAWBACKS |

DRAWBACKS |

| More chemical detergents used | Higher cost due to the presence of the heating syste |

| Reduced effectiveness on oily dirt, resulting in increased work time | Higher energy costs for the boiler suppl |

| Higher water consumption than hot water models | More frequent maintenance required |

High pressure washers with electric motor and endothermic engine

High pressure washers can also be macro-classified according to the type of motor/engine they are powered by:

- With electric motor

They are quieter and lighter than washers powered with endothermic engine. However, it is of course necessary to have a power supply appropriate to the motor’s power.

There are two types of electric motors: either with brushes exclusively intended for hobby use or magnetic induction, which instead represent the majority of the market share and are mounted on the entire Comet range with the exception of the small KRM, KRS and KRX models. In turn, the induction motors are divided into:

Single-phase asynchronous motors, which use the standard voltage in homes.

Three-phase asynchronous motors, which use the voltage present in industrial plants.

- With endothermic engine (internal combustion engine)

They are usually cold water high pressure washers and represent the ideal solution when the electrical connection is not available in the working area or where the latter does not reach the adequate power. They are therefore suitable for building or road construction sites, farms and any other business where a fully autonomous and easily transportable high pressure washer is required. They can be fuelled by petrol or diesel.

Again, there is no better solution a priori, but both categories have advantages and drawbacks that must be taken into consideration when making a choice.

| HIGH PRESSURE WASHERS WITH ELECTRIC MOTOR | HIGH PRESSURE WASHERS WITH ENDOTHERMIC ENGINE |

|---|---|

| ADVANTAGES |

ADVANTAGES |

| Less engine noise | Faster cleaning time |

| No exhaust gases | Less chemical detergents used |

| DRAWBACKS |

DRAWBACKS |

| External power source required for connection | High engine noise |

| Potentially less verifiable supply costs | Can’t be used in closed environments |

Professional, semi-professional and domestic high pressure washers

The choice of a high pressure washer is very often related to the type of work the machine will have to do.

There are a multitude of different models in terms of cost and performance designed according to users’ needs in relation to the environment, the type of dirt to be removed and the type of surfaces to be cleaned.

According to a series of parameters (pressure, flow rate, motor power, voltage, components used, etc.) we can mainly distinguish among five macro-categories:

High pressure washers for domestic use

High pressure washers for semi-professional use

High pressure washers for heavy-duty semi-professional use

High pressure washers for professional use

High pressure washers for heavy-duty professional use

Applications

Domestic and semi-professional washer applications

The high pressure washers in the Comet range are considered a top-range product with good performance and maximum reliability. High pressure washers for domestic and semi-professional use therefore range from individual consumer hobbies (cleaning of outdoor areas such as balconies, courtyards, swimming pools, campers, caravans, cars, etc.) to the use in craft businesses such as workshops, laboratories, small farms, etc..

Professional washer applications

The Comet range of professional high pressure washers has been designed for any type of need with high performance and reliability. Our high pressure washers are used in many sectors such as workshops and car washes, shipyards, cleaning companies, industries, hospitals, farms, transport, etc..

Comet high pressure washers: a complete range

Comet high pressure washers are divided into 3 macro families distinguished by a reference colour:

- blue identifies electric cold water high pressure washers

- yellow identifies high pressure washers with internal combustion engine (cold and hot water)

- red identifies electric hot water high pressure washers

| COLD WATER | COLD AND HOT WATER | HOT WATER | |

|---|---|---|---|

| SEMI-PROFESSIONAL DOMESTIC USE | BLUE SERIES COMMERCIAL | RED SERIES COMMERCIAL | |

| HEVY-DUTY SEMI-PROFESSIONAL DOMESTIC USE | BLUE SERIES STATIC | ||

| PROFESSIONAL USE | KSTEEL BLUE SERIES PROFESSIONAL |

X SPECIAL COLD WATER X SPECIAL HOT WATER |

RED SERIES COMMERCIAL |

Blue series commercial

The Blue Series Commercial high pressure washers have performance and components suitable for domestic or semi-professional use.

The KRM, KRS, KRX, KLS and KL models are recommended for occasional use and on small surfaces.

The KL/KLS 1600 GOLD and KL/KLS 1680 GOLD PLUS models can also be used with particularly difficult dirt and in the presence of particularly hard water, thanks to the higher-range performance and the motor pump equipped with brass head.

The KSM, KS and KT semi-professional high pressure washers are suitable for more frequent use, for particularly difficult dirt on medium surfaces. The KA washers are also suitable for heavy-duty use, especially in the 4000 and 5000 models that boast a three-phase motor.

Blue static/portable Series

The Blue Static/portable Series high pressure washers have no wheels but at the same time feature extreme manoeuvrability and ease of transport. The STATIC models are designed to guarantee the utmost stability thanks to the possibility of wall mounting, but can also be used in mobility thanks to the possibility of its use on the ground. The product’s versatility is especially evident when equipped with the hose reel (standard for STATIC 1700-1900 models, optional for K 250 STATIC).

Thanks to these features, the STATIC 1700-1900 washers are usually recommended in houses with garage. The K 250 STATIC washers, on the other hand, are perfect for the food industry (butcheries and dairy industry) and mechanical workshops.

The PORTABLE models, as the name suggests, are compact and easily transportable, equipped with both electric motor (KR portable/K Premium Pick-up) and combustion engine (ETM). The three models in the range are suitable for all types of use. The KR portable washer is ideal for domestic use, the ETM model is designed for semi-professional use, while the K Premium pick-up version is ideal for professional use, especially in workshops and car washes, also thanks to the Static kit that allows it to be wall mounted.

Blue series professional

The Blue Series Professional high pressure washers are machines for a continuous use.

The K 200 represents the entry level of the professional cold water washer; this is a model suitable for the demanding professional who uses the high pressure washer continuously but not too heavily.

The K 250 and K PREMIUM models, both equipped with delayed Total Stop, are specifically designed for a continuous heavy-duty use (e.g. car washes).

The K 250, one of the most appreciated Comet products on the market in terms of design and performance, uses the power of the COMET LW-K 250 Pump, with 3 solid ceramic plungers, oil level indicator, brass head.

The K premium model, thanks to the sintered bush coupling between motor and pump, the Comet RW Premium pump and oversized motors (in relation to the performance developed by the pump) ensures unique reliability.

Blue series K Steel

The K Steel series high pressure washers are all cold water models for a continuous and heavy-duty professional use, with a painted steel frame and stainless steel cover (the K STEEL ECO models also have a stainless steel frame), dedicated to demanding professionals.

The K 891-K991, K 1251-1501 and K XTREME models are fitted with Comet Premium pumps, while the motor/pump coupling is made by means of an elastic joint for the K 1251/1501 and K XTREME models.

Within the range there are various sizes of 4-pole and 1,400 rpm electric motors (powers from 3 to 30 Hp), all with thermal cut-off and contactor device, pressures from 120 to 500 bar and water flow rates from 11 l/min to 42 l/min.

The high pressure washers of this series are conceived for the building industry (plaster removal and sandblasting), naval field, steelworks, foundries, and in all environments where powerful machines in terms of pressure and flow rate are required.

X-Special cold water

The high pressure washers of the X-Special Cold Water series are cold water machines equipped with 4-stroke endothermic engines (petrol and diesel). They are ideal for use on construction sites or in all those situations where there is no electricity.

The range includes:

- semi-professional machines (FDX 2, FDX WB and PTO), where the engine/pump coupling is direct (3,400 rpm) and LONCIN and HONDA engines from 6 to 13 Hp are used

- professional machines (FDX BLADE XL – FDX ENDURANCE), where the coupling is made by means of a gearbox (1560 rpm) and HONDA petrol engines up to 11 Hp or YANMAR diesel engines up to 13 Hp are used

- highly professional machines (FDX XTREME/XTREME XL), where the engine/pump coupling is always done by means of with the gearbox (1560 rpm) and the HONDA/VANGUARD petrol and KHOLER diesel engines reach up to 22 Hp

X-Special hot water

The X-Special Hot Water series includes a single high pressure washer, the FDX HOT CUBE, as well as two models of mobile hot water generators (HOT BOX).

The FDX HOT CUBE is a self-contained unit for a continuous professional use, with HONDA petrol or YANMAR diesel endothermic engine, equipped with a high performance stainless steel boiler for hot water and steam operation up to 140°

The machine is recommended for building or road construction sites and for all professional uses where the connection to the power mains is impossible. It is equipped with all the necessary requirements to ensure reliability and safety during use: electric start, decelerator, electronic temperature regulation system with a low variation of the set value, burner operated by the flow switch and flame control kit.

Red series commercial

The Red Series Commercial high pressure washers are suitable for domestic and semi-professional use.

The PATRIOT model, despite being the entry level of the hot water range, has construction characteristics above the market average. In particular, the 150 Gold model has the pump with brass head and the safety valve on the boiler, and is a product suitable for a quite frequent use on medium-sized surfaces with quite difficult dirt.

The SCOUT models can also be used for a frequent use and with particularly difficult dirt on medium/large surfaces, thanks to their high performance in terms of pressure/flow rate and the motor pump with brass head. The machine is recommended to the demanding individual consumer and to craftsmen (car mechanics, body repairers, plumbers, etc.) who use the high pressure washer frequently but not continuously.

Red series professional

The Red Series Professional high pressure washers represent the best offer on the professional market in terms of performance and construction quality.

With the KP and KP PRO models we have introduced two models with single-phase and three-phase entry level electric motors, suitable for a professional, not heavy-duty use.

The KM models, on the other hand, are machines structurally and conceptually designed for a continuous professional use: the wide range of single-phase or three-phase models and the possibility of customization with water tank, descaler reservoir and electronic controls represent the best products available today on the market.

Finally, the KF and KF STEEL models are the ”top-of-the-range” versions of the entire Comet production.

They take up the construction concepts of the KM series but have technical characteristics that make them also suitable for heavy-duty and continuous professional use (Comet Premium pumps, self-contained ventilation units and high quality boilers).

How a high pressure washer works

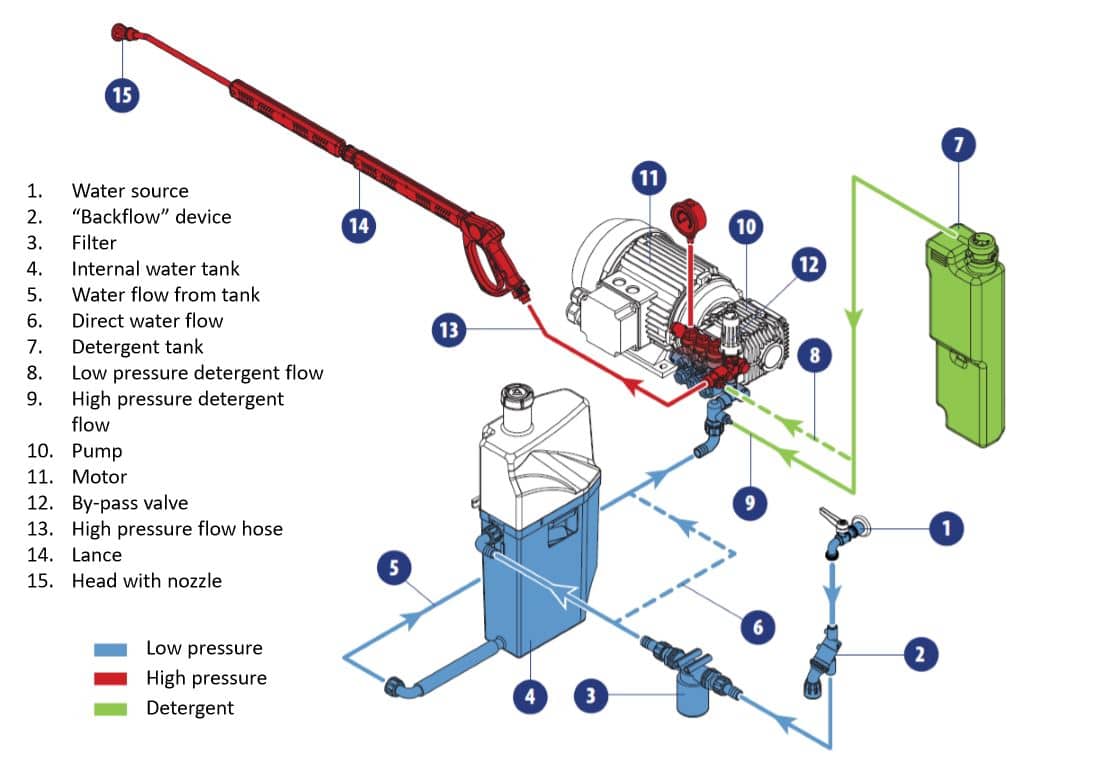

In this diagram we can broadly see how a high pressure washer works.

Cold water coming from a water source (1) passes through a special filter (3) and is fed into the pump (10), driven by an electric motor or an endothermic engine (11).

If the water comes from a drinking water source, it must pass through a “Backflow preventer” device (2) necessary to prevent any backflow, before reaching the pump.

The pump produces a high-pressure jet at outlet, which is regulated and limited through a bypass valve (12) before passing through a hose (13) and ending its path exiting through a rigid lance (14) in the head of which a nozzle (15) is fixed.

A detergent may be added to the water flow from a tank (7), which may be introduced upstream (8) or downstream (9) of the pump. In case it is added upstream of the pump (usually on machines with internal water tank) we talk of high pressure detergent delivery, while in case (8) it is added downstream of the pump we talk of low pressure detergent delivery.

In this latter case the pump is generally supplied directly (6) from the water source (1). In the low pressure delivery (8) the detergent is sucked in by means of a Venturi system and an excellent foam effect is generated. In the high pressure delivery, on the other hand, the detergent is sucked in simply by connecting the detergent hose (9) to the pump suction, in this case no pressure drop is generated yet the foam effect is much more limited.

The main components of a high pressure washer are:

- Water inlet filter

Each high pressure washer is connected to a water source from which it draws its water. A suction filter is usually positioned at the inlet in order to stop dust and any debris that could damage the machine. - Motor/engine

As said before, the high pressure washers may be powered by an electric motor (single-phase or three-phase) or by an endothermic engine (petrol or diesel). - Piston pump

The pump is the core of the high pressure washer; there are two main types of pumps: axial (or axial piston) and triplex (or in-line piston). - Unloader (and bypass) valve

Its main task is to regulate the pump pressure up to the maximum settable value, discharging (by-passing) the excess water flow towards the low pressure area (in the tank or inside the head itself). It also operates as a safety valve in case of blocked nozzle or closed lance, always thanks to the discharge towards water. - Pressure gauge

It is a device that indicates the pressure of the liquid in the pump head. It can have a plastic or stainless steel casing and the internal meter is dipped in a glycerine bath to dampen oscillations. - Detergent tank (or detergent lance)

Depending on the type of high pressure washer, the detergent is sucked in and mixed with water coming from a tank built in the high pressure washer, or by means of a foaming kit - Boiler

On the hot water washers there is always a boiler, inside which the water passes through a metal coil heated by a burner and is then fed into the delivery hose, at a temperature usually between 90° and 140° depending on the power of the boiler - Control panel

On high-end models, the on/off switch can be found in a control panel that allows controlling and regulating the functions of the high pressure washer. - Water supply reservoir and descaler device

Some models of Comet high pressure washers are equipped with an internal water supply tank, equipped with a float for filling control. This tank can be combined with a descaler kit consisting of a tank and an electric descaler dosing unit. During hot water operation, the dosing unit sucks in the descaler liquid from the tank and feeds it into the internal water tank, in order to prevent any scale from forming inside the delivery circuit of the high pressure washer. - Backflow preventer

According to the current Community Directives, water passing through a high pressure washer is no longer considered drinking water. For this reason a high pressure washer cannot be connected directly to the drinking water mains without first installing a BA type backflow preventer.

Comet’s BA10 Backflow Preventer is compatible with all high pressure washers and performs this dual function: to protect against possible legal sanctions and safeguard health.

Accessories

Thanks to a wide range of accessories the high pressure washers may be used for different applications and uses. Comet markets an extensive catalogue of accessories for high pressure washers for both domestic and professional use to ensure excellent performance for every type of use.

Guns

It’s connected to the high pressure washer’s delivery hose and is used to control the jet and determine through a lever whether the water is flowing out or not. A lance is attached to its end.

The guns with flow regulator also allow modulating the force of the outgoing water jet, thus regulating the pressure and flow rate at the nozzle of the lance proportionally.

Lances

This is a rigid metal or plastic tube that is connected to the gun by means of a quick coupling. At the opposite end of the head is fixed the nozzle from which the pressurized water flows out. There are different types of lance, depending on the type of use they are intended for: high pressure lances (straight or angled) with fixed head or with detergent suction regulation for washing and application of detergents, or foam lances equipped with a tank for dispensing sanitizing detergents. The detergent mixed with water using the “Venturi” system generates a thick and effective foam.

In the Comet range we also find sand-blasting lances, which are particularly useful when removing rust, paint and incrustations; the jet power is, in fact, amplified by the water-mixed sand or soda sucked in by the probe.

Nozzles

The nozzle is a device designed to spray water with a certain shape and direction. The nozzles can be made of brass, stainless steel or ceramic and are distinguished by the shape of the jet:

Concentrated or 0° grade jet nozzle: the water comes out of the nozzle orifice forming a concentrated jet whose internal volume is filled with drops; it is suitable in case of very concentrated and resistant dirt.

Flat or fan-shaped nozzle: the water comes out of the orifice forming a fan-like jet, with an opening angle normally between 15° and 40°; this is the most suitable solution for most surfaces.

Rotating nozzle: the water comes out of the orifice forming a rotating conical jet, where the drops are distributed only on the outer surface, improving the cleaning effect. The rotating action does in fact increase the impact pressure on the surface.

The choice of the most correct nozzle therefore depends on its use, the more resistant is the surface (and the dirt’s concentration), the smaller will be the opening angle width to be used. Conversely, the more delicate is the surface (or surface dirt) the greater will be the angle.

Each application has its own specific nozzle like the nozzles for pipe flushing probes.

Delivery hoses

This is the hose that connects the high pressure washer to the gun. A standard hose would not be able to withstand the high pressure generated by the flow of water through it. The delivery hose is then reinforced with single or twin (metal or plastic) plaits and several layers of high density rubber.

Heads

The heads have a dual function, they connect one or more nozzles at the same time to the lance and at the same time protect them from shocks or external stress, so as to limit wear. Depending on the type of use or need, it is possible to choose from nozzle holder heads, detergent suction heads, double and triple heads for mounting more than one nozzle, heads for sandblasting lances and for pipe flushing probes.

Brushes and surface cleaners

To cover the different areas and needs for cleaning and sanitation, the high pressure washers can be equipped with a complete range of fixed and rotating brushes ideal for car-wash as well as surface cleaners for washing outdoor areas: patios, pavements, walls. The Comet range of accessories also includes a complete kit for washing solar panels equipped with telescopic extension and ultra-light surface cleaner. A gutter washer kit can also be implemented on request.

Other accessories

In the Comet range of accessories for domestic, semi-professional and professional high pressure washers, we also find: ejectors, swivel couplings, filters, hose reels, descaler dispensers, and other accessories dedicated to specific uses or particular needs.

Special characteristics of the Comet high pressure washers

- Total Stop

This is a special function that automatically stops the high pressure washer with electric motor when the gun is closed (no water flow at the pump delivery), bringing it to stand-by. When the gun is reopened, the machine being still energized, the washer restarts.

The Total Stop device can be instantaneous (TSI), if the motor switches off at the same time as the gun is closed, or delayed (TSR), if the motor switches off approximately 15 seconds after the gun is closed.

To avoid leaving the machine live for too long, a safety device (general stop) that switches the machine off after 15 minutes is provided in some models.IMPORTANT: During Total Stop the high pressure washer is fully operational.

If you move away during use it is always necessary to switch off the high pressure washer, relieve the residual pressure by pulling the gun trigger and disconnect the electrical cable from the power socket. In case of spontaneous restart from Total Stop condition the problem can be caused by leakage in the delivery circuit; its soundness must be checked. - Easy start

A device that reduces the in-rush torque of the motor pump by assisting the start of the electric motor in precarious connecting conditions, e.g. in case of voltage dips. - Self-priming capacity

Some models of Comet high pressure washers can work in self-priming mode and can be powered by an external source (e.g. tank). - Thermostatic valve

Some models of Comet high pressure washers are equipped with a thermostatic valve. This device prevents pump seals from overheating during the prolonged operation in by-pass.

Useful tips to get the most of your high pressure washer

Want to get the most out of your high pressure washer? Here are a few useful tips and tricks:

- For cleaning vertical surfaces, wash from bottom to top and rinse from top to bottom.

- Regularly check that the inlet water filter and the nozzle on the lance are clean

- Using too much detergent makes rinsing more difficult and pollutes the environment. Better not overdo it.

- Keep the nozzle at an angle to the washing surface and at a sufficient distance to avoid damaging the surface itself.

- Always avoid spraying water on lighting or air conditioning systems, electrical sockets or air vents.

- Keep the jet moving to prevent water from damaging the surfaces.

Special characteristics of the Comet high pressure washers

- Total Stop

This is a special function that automatically stops the high pressure washer with electric motor when the gun is closed (no water flow at the pump delivery), bringing it to stand-by. When the gun is reopened, the machine being still energized, the washer restarts.

The Total Stop device can be instantaneous (TSI), if the motor switches off at the same time as the gun is closed, or delayed (TSR), if the motor switches off approximately 15 seconds after the gun is closed.

To avoid leaving the machine live for too long, a safety device (general stop) that switches the machine off after 15 minutes is provided in some models.IMPORTANT: During Total Stop the high pressure washer is fully operational.

If you move away during use it is always necessary to switch off the high pressure washer, relieve the residual pressure by pulling the gun trigger and disconnect the electrical cable from the power socket. In case of spontaneous restart from Total Stop condition the problem can be caused by leakage in the delivery circuit; its soundness must be checked. - Easy start

A device that reduces the in-rush torque of the motor pump by assisting the start of the electric motor in precarious connecting conditions, e.g. in case of voltage dips. - Self-priming capacity

Some models of Comet high pressure washers can work in self-priming mode and can be powered by an external source (e.g. tank). - Thermostatic valve

Some models of Comet high pressure washers are equipped with a thermostatic valve. This device prevents pump seals from overheating during the prolonged operation in by-pass.

Useful tips to get the most of your high pressure washer

Want to get the most out of your high pressure washer? Here are a few useful tips and tricks:

- For cleaning vertical surfaces, wash from bottom to top and rinse from top to bottom.

- Regularly check that the inlet water filter and the nozzle on the lance are clean

- Using too much detergent makes rinsing more difficult and pollutes the environment. Better not overdo it.

- Keep the nozzle at an angle to the washing surface and at a sufficient distance to avoid damaging the surface itself.

- Always avoid spraying water on lighting or air conditioning systems, electrical sockets or air vents.

- Keep the jet moving to prevent water from damaging the surfaces.