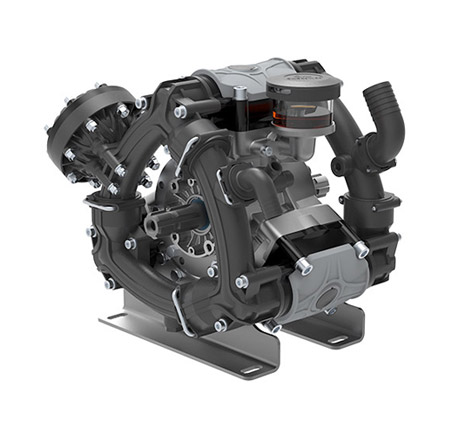

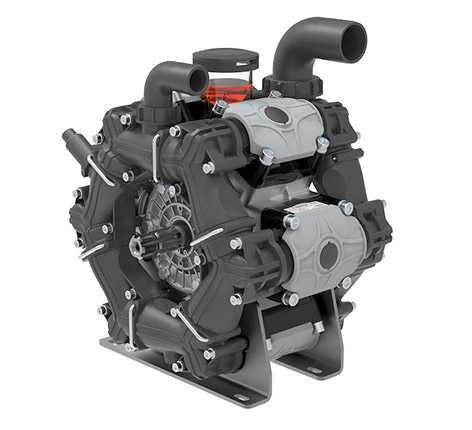

BPS SERIES

The new range of Comet 3 to 6 diaphragm low-pressure pumps

The BPS line boasts a series of major features unparalleled on the market: reduced overall dimensions, ease of maintenance, long life and resistance to heavy duty operating conditions, while always providing high performance in terms of flow rate, priming capacity, power absorption and silent running.

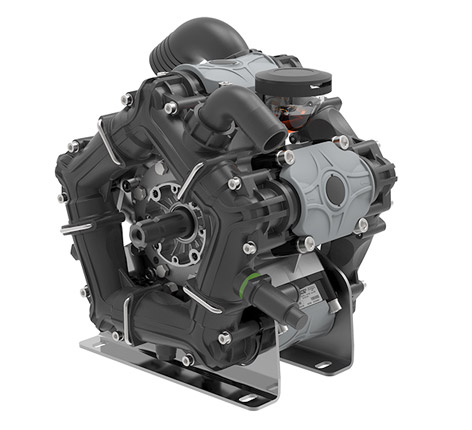

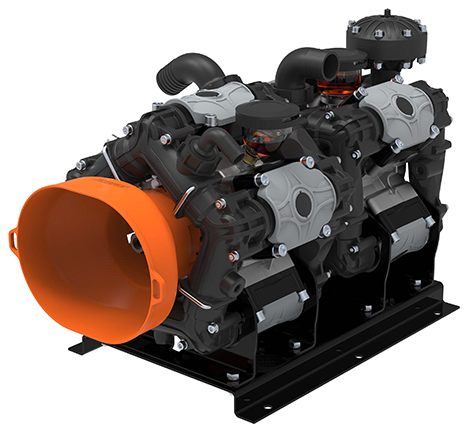

The BPS range includes 4 pumps with 20-bar max pressure and flow rates of 160, 200, 250 and 300 l/min, designed for the most modern and high-performance boom-sprayers. All the pumps of the BPS range can be coupled in tandem to increase flow rates or obtain multipurpose synchronous applications (spraying /agitation/ constant recirculation).

On request, the pumps can be equipped with: safety valve, PTO guards (mandatory in EU), pressure dampers (standard on BPS 160 and 200).

What is more, to optimize the after-sales service, most of the spare parts are common for all the models of the range.

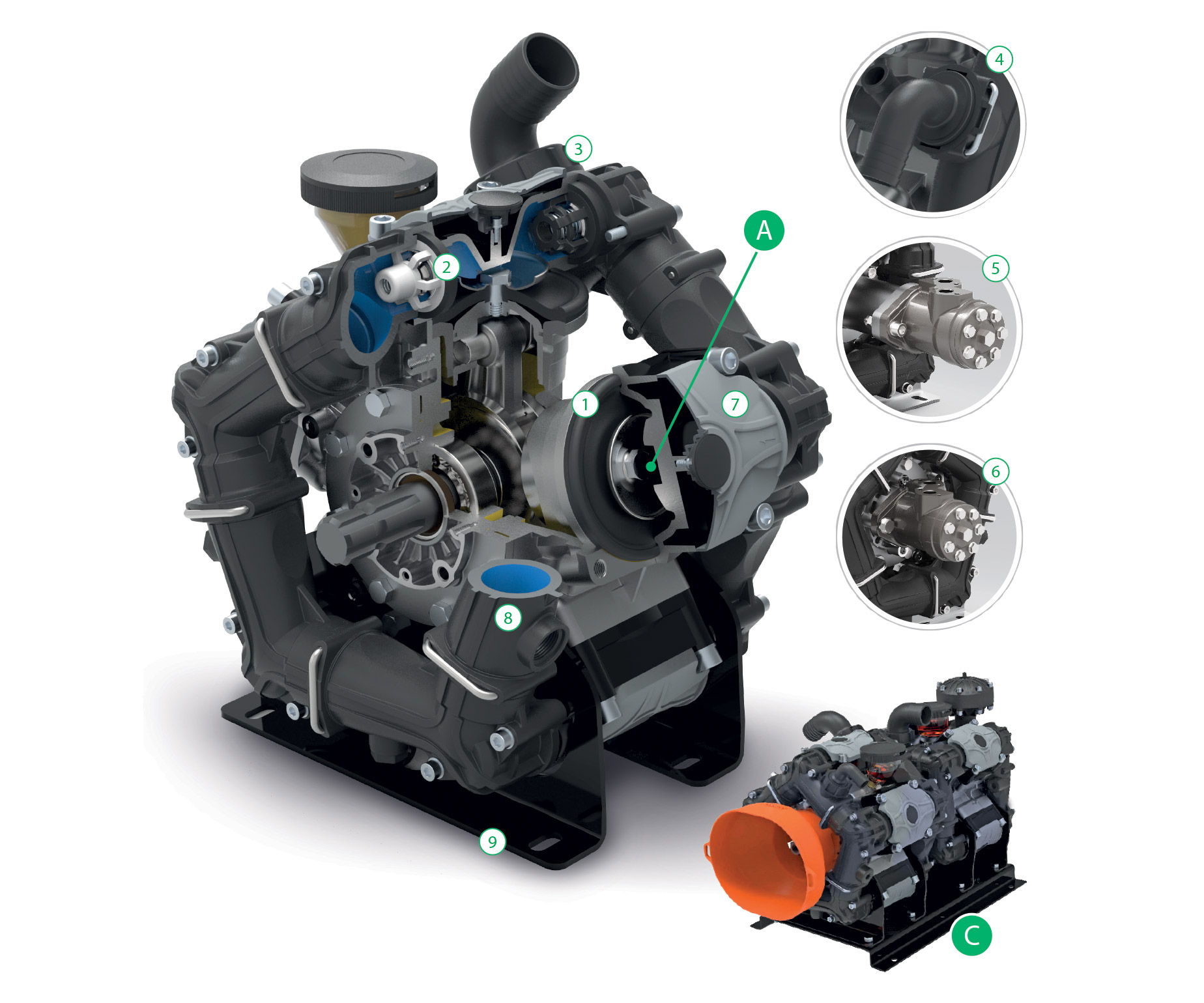

HIGHLIGHTS

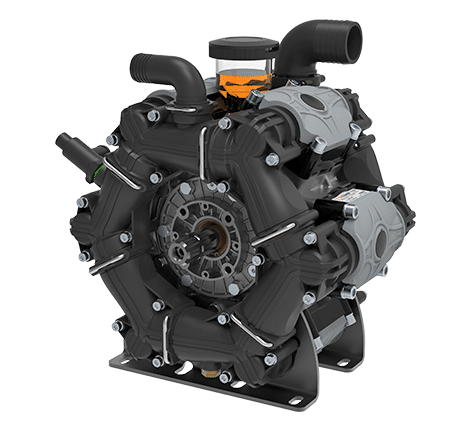

LOW-MAINTENANCE

Over-sized diaphragms and reduced piston stroke provide maximum durability for diaphragms, check valves and consumables. Drain plugs on both manifolds to prevent icing issues.- PERFORMANCE

Short-stroke pistons, oversized diaphragm (1) and check-valves (2) with innovative fluid slots and spring loads allow unique priming capacity, flow-rate accuracy and shut-off speed. - MODULARITY

Pumps can be coupled in “tandem” to expand the flow-rate of for multi-purpose applications. - VERSATILITY

Hose barbs available in fly-nut threaded (3) or clip-coupling version (4). Shaft plugs available in 1” 3/8 splined M or F (5); 25 or 32 Ø mm F (6). - OUTSTANDING MATERIALS

Plastic-coated aluminium heads (7). Stainless steel – techno polymer check-valves. Manifolds and fittings in high tech polymers (8). Doublecoated steel-made holders (9). Diaphragms in NBR and Desmopan.

APPLICATIONS AND USES

BPS PUMPS

RELATED HIGHLIGHTS

APS SERIES

The global benchmark for spraying pumpsThe global benchmark for spraying pumps

The APS series is the international byword for highpressure spraying pumps. This exceptional reputation has been achieved by Comet through decades of technological improvements, in order to meet the most demanding needs of customers looking for a pump that is simple to use, reliable and heavy-dut.

IDS SERIES

The indestructible Comet High-Pressure brass pumpsThe indestructible Comet High-Pressure brass pumps

The IDS series is Comet’s top-of-the-range, and it is world-known for its unmatched reputation in the field of brass pumps. IDS pumps have been engineered for heavy-duty applications in orchards, vineyard and olive crops and are capable to adapt to the harshest conditions.